Design Rules

1. Attention (5 Min.)

In the world of robotics, building a sturdy and well-designed robot is crucial for success in competitions. Building principles encompass a set of guidelines and techniques that ensure your robot's structural integrity, functionality, and overall performance. By understanding and applying these principles, you can create a solid foundation for your robot, minimize mechanical failures, optimize efficiency, and ultimately enhance your chances of achieving your goals in the VEX robotics realm. But what happens when you don't build with good principles?

2. Learners Guidance

Rolling Robots Rules to Build Cool Robots

There are no instructions for building competition robots, rather we follow a set of rules. Using Design Rule Checking is an engineering practice to assure that all designs that we produce will have a high chance of being successful. It is well known and defined in the semiconductor chip industry but also applied to other design projects typically when using a common manufacturing process. Ou common manufacturing process is the use of the VEX Robotics product line. Through years of experience we have learned best practices when using the VEX Robotics product line and developed rules of building that will assure that your robots function as expected. Follow these rules while building and your robot wont fall apart on the field.

Design Rules also give us a clear way to communicate problems or errors in the design. When reviewing a design we can simply quote a design rule that we all know instead of having to make a detailed description of what is wrong. With this language of design we can all assist one another in the building process. Learn the language of the Design Rules to become fluent in the Rolling Robots Design Process.

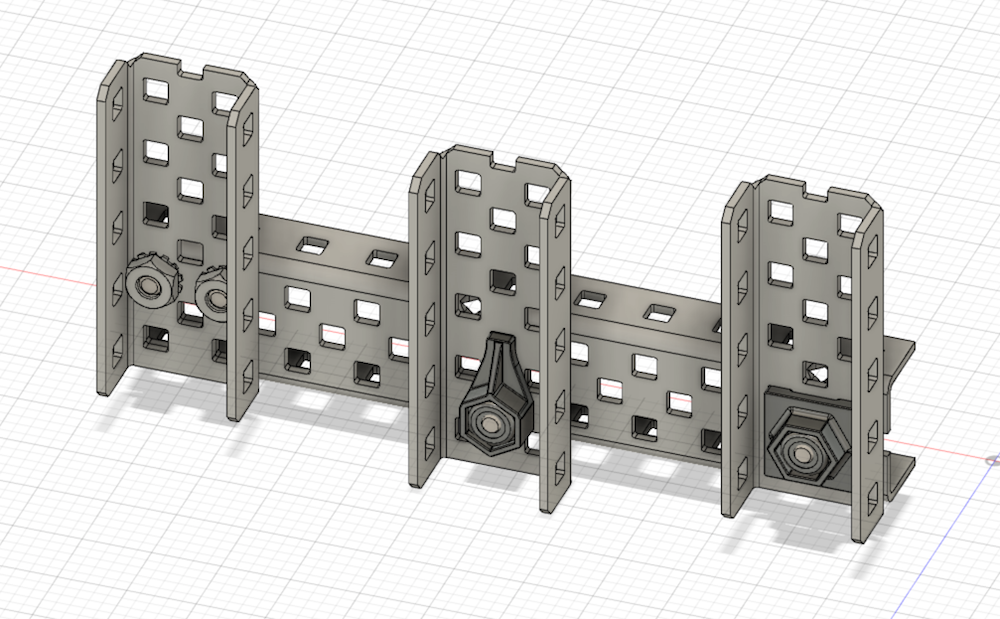

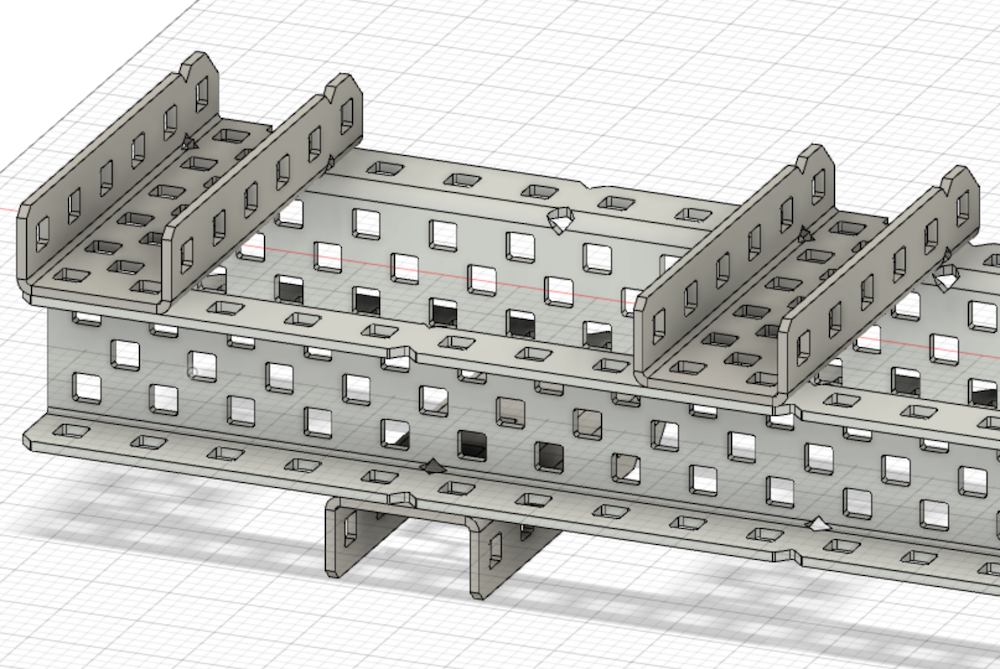

2 Points make a line, 3 points make a plane

This is basic geometry applied to robot building

Always use at least 2 points of fastening when joining parts. This usually means 2 screws through the parts. this rule can also be satisfied by using the hex nut retainers with posts. In that case the posts provide the additional points for stability.

If you want to hold 2 parts parallel to each other we must define 2 planes. Connecting with cross rails at 3 points will do this.

Another way to do hold a plane is to use standoffs. Sometimes it is not possible to get the exact length of standoff but you can extend with spacers to make it perfect.

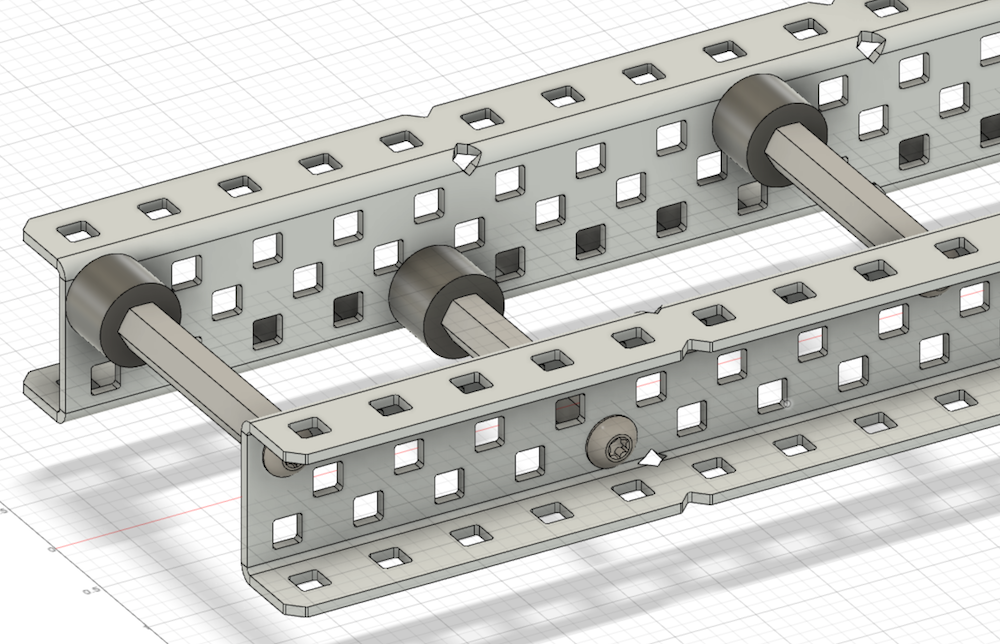

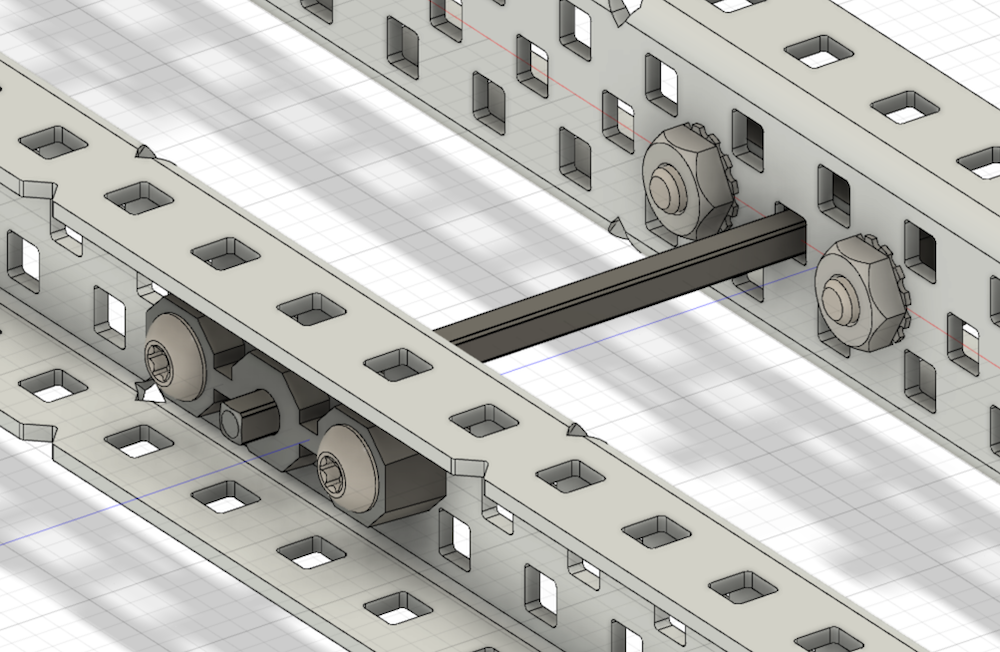

No metal moving on metal

Use plastic bearings and spacers. Wherever we have a metal part that needs to move it should be supported by a plastic part. Usually the plastic part should be made from a bearing material like Nylon or Delrin. These materials are strong and low friction. The bearings are Delrin, the spacers are nylon.

Shown here is an axle and a bearing. The turning metal axle is supported by the bearing that is made of a special plastic that has low friction. Also the bearing has a round hole that supports the axle more snuggly. Also shown in this design is 2 points of support for the axle. Any axle should be supported by bearings in at least 2 points.

Use locking fasteners

Star Nuts, Nyloks, Lock Tite

Star Nuts lock by the washer biting into the metal to resist turning. They depend on being tight. Use them for all metal to metal connections and tighten them well.

Nyloks lock based on a piece of nylon plastic providing friction in the nut. The will remain in place even if they are not completely tightened. Use these for applications where the joint is expected to move and needs to be not too tight. Also use these when fatening plastic items like bearings, hex nut retainers etc. This way we do not tighten too tight that may deform the plastic.

In places where there are no locking mechanism like standoffs and motor screws we may use locktite. Locktite is kind of a glue for metal fasteners There are different strength levels we use a special locktite 222 as it is locking but easy to remove.

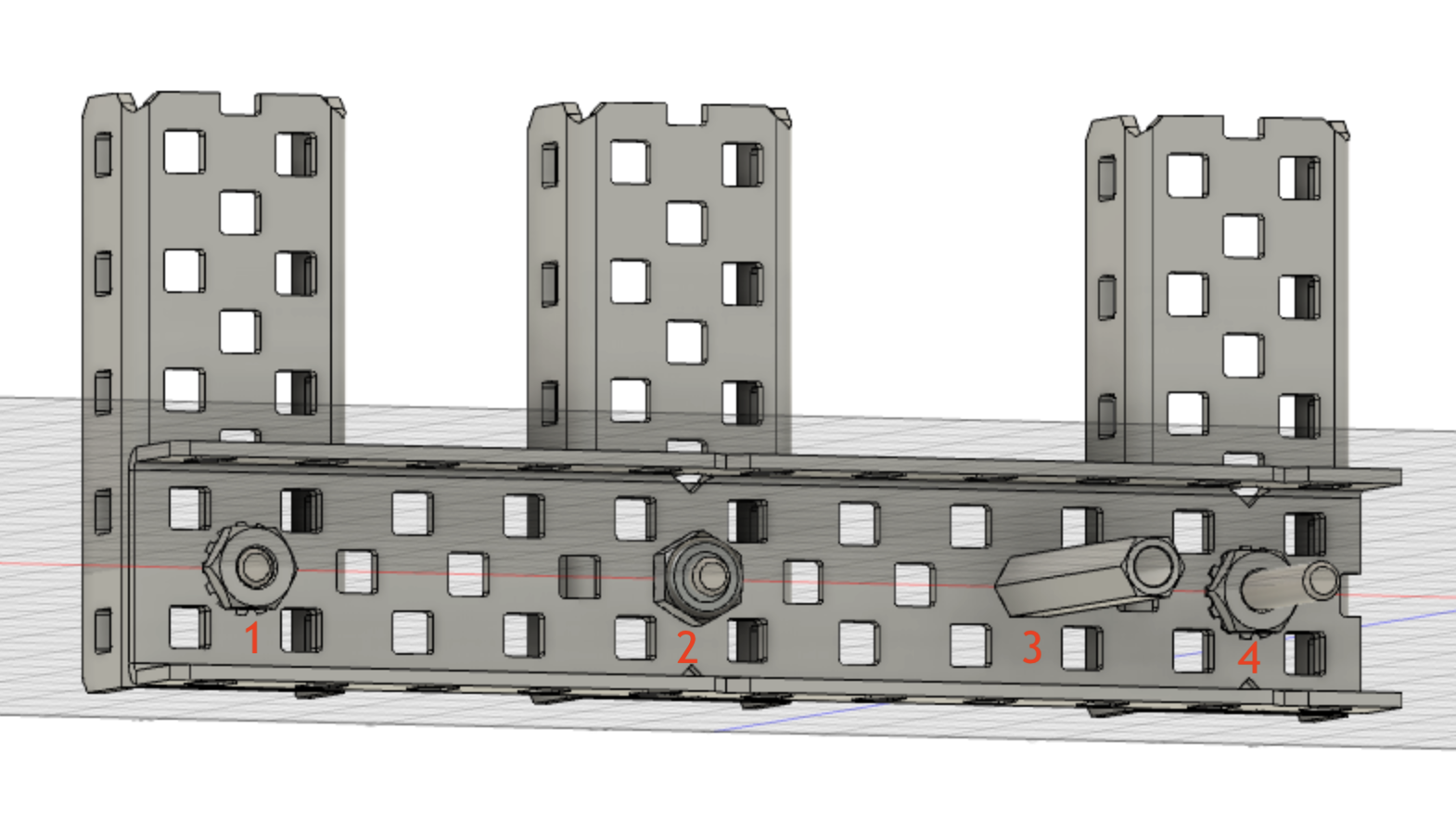

Here is a sample of locking fasteners

- Star or Keps Nut, the teeth go towards the metal surface

- Nylock, a piece of nylon provides friction against unscrewing, stays on even when loose

- Standoffs have no locking, so you may have to use Locktite

- This screw is too long, don't do this

What errors do you see in this assembly?

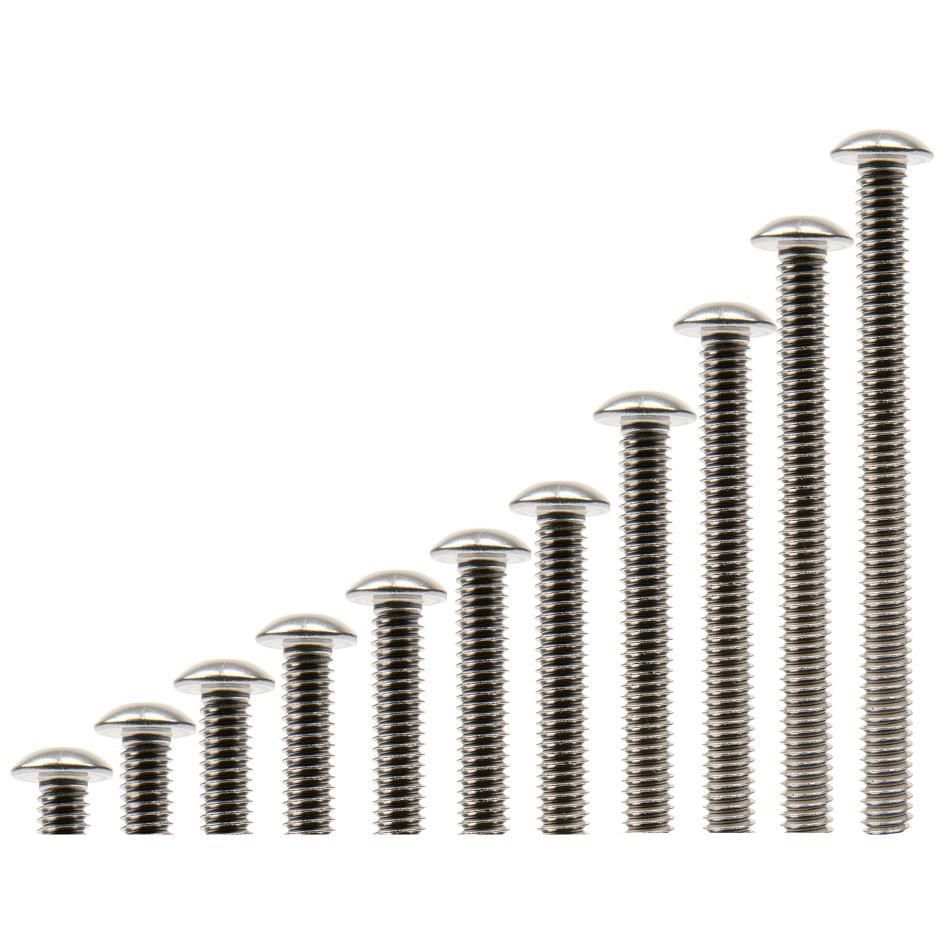

Use the correct length screws

Excessive length of the screws wastes time and annoys the pig. Most of our screws come in 1/8 increments of length so if there is more than 1/8 of an inch sticking out of the nut then the screw is too long. (on longer screws over 1 inch the increment is 1/4 inch)

The screws we use are 8-32 star drive. The Screws come in increments of 1/8 of an inch.

Triangles define angles

The triangle is your friend

3. Explore (25 - 30 Min.)

Have the student try to build a 3 Dimentional structure using c-channels without using any triangles. After about 10 minutes, take turns putting force on the structures to show how easy they bend or warp. Then, add more c- channels to form triangles. Once everyone is done, show how the structures are much more stable with the triangles than without.

4. Closure (5 Min.)

Have the students reflect on the importance of good building principles and discuss how they plan to incorporate them into their robot.