Working with Poly Carbonate

The Vex Robotics Competition allows for custom parts to be fabricated using a limited amount of "non-shattering" plastic. The specific rule for the 2022-2023 season is:

R9. A limited amount of custom plastic is allowed. Robots may use custom-made parts cut from certain types of non-shattering plastic. It must be possible to have cut all of the plastic parts on the Robot from a single 12” x 24” sheet, up to 0.070” thick.

a. The intent of the area / thickness constraints is to limit the number of custom plastic parts used in Robot construction, not to define an absolute volume. For example, using a sheet which is 0.035” thick does not permit two 12” x 24” sheets’ worth of parts.

b. Plastic parts do not have to be literally cut from the same original 12” x 24” sheet. However, all individual parts must be able to “nest” or rearrange into a 12” x 24” area. A collection of parts which theoretically have a total surface area of 288 in2, but cannot be nested onto a single 12” x 24” sheet, would not be legal.

c. Plastic may be mechanically altered by cutting, drilling, bending, etc. It cannot be chemically treated, melted, or cast. Heating polycarbonate to aid in bending is acceptable.

d. Legal plastic types include polycarbonate (Lexan), acetal monopolymer (Delrin), acetal copolymer (Acetron GP), POM (acetal), ABS, PEEK, PET, HDPE, LDPE, Nylon (all grades), Polypropylene, and FEP.

e. Shattering plastic, such as PMMA (also called Plexiglass, Acrylic, or Perspex), is prohibited.

f. The PET Sheet Variety Pack (276-8340), sold by VEX, is considered “plastic” in the context of this rule, and is subject to the same limitations as “off-the-shelf” plastic sheets.

g. This rule does not apply to 3D printed plastic parts. 3D printed parts are not permitted in the VEX Robotics Competition, except as non-functional decorations (per ) or as custom License Plates.

The plastic that we typically use is poly Carbonate sheet 1/16 inch thick. 1/16 inch = .0625. so is valid under the .07 inch limit. We purchase this plastic in 12 by 24 inch sheets. We also occasionally wil re-use platic sheets from prior years field elements. As long as the plastic is the correct type and thickness it is ok to use.

Fusion 360 Design

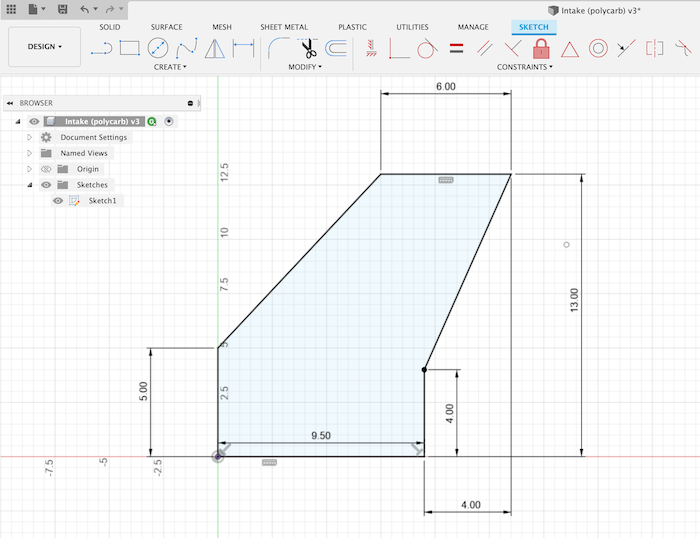

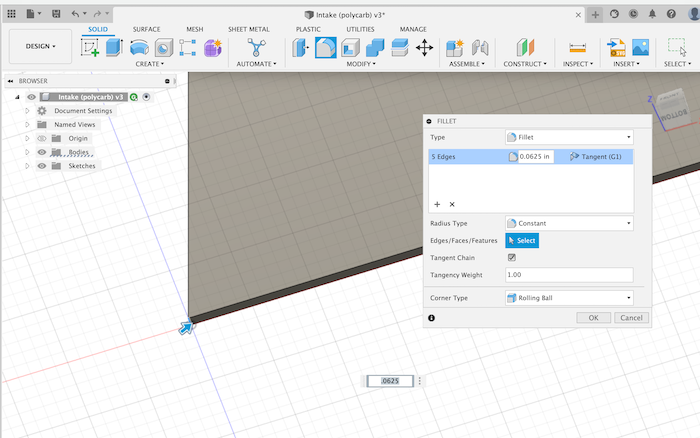

Fusion 360 is used for design of the polyCarb parts. It is primarliy 2D sketching with the use of constraints and dimensions. One can go a little further and extrude the parts to the .0625 thickness creating a body in fusion , and then save it as a component to use in other assemblies. Fusion 360 skecth can also be used to determine if our parts could be cut from a single sheet of material.

You start with a sketch. Use the tools from the crayola cad lesson, lines, circles, constraints and dimensions to create a closed shape.

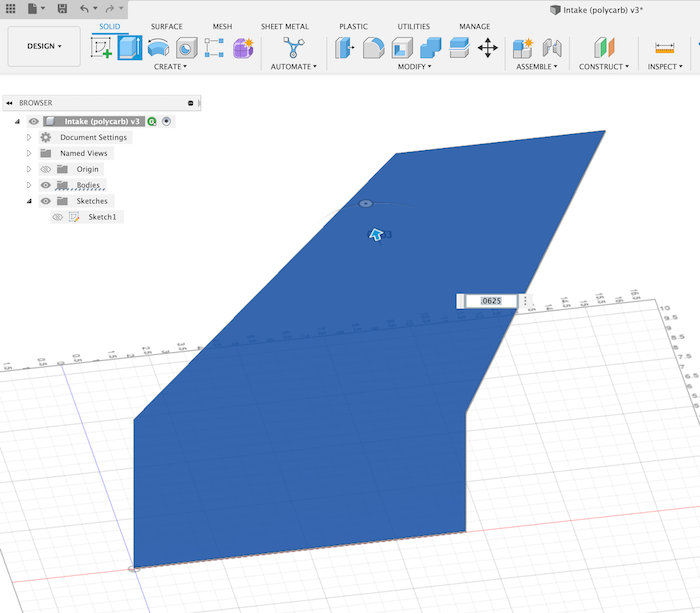

Use the extrude tool to make the part the thickness you would like it to be. Extruding will create a Body. When completed find the body in the browser list, right click and select create component. Save the file. Now you have a part that you can insert into other designs.

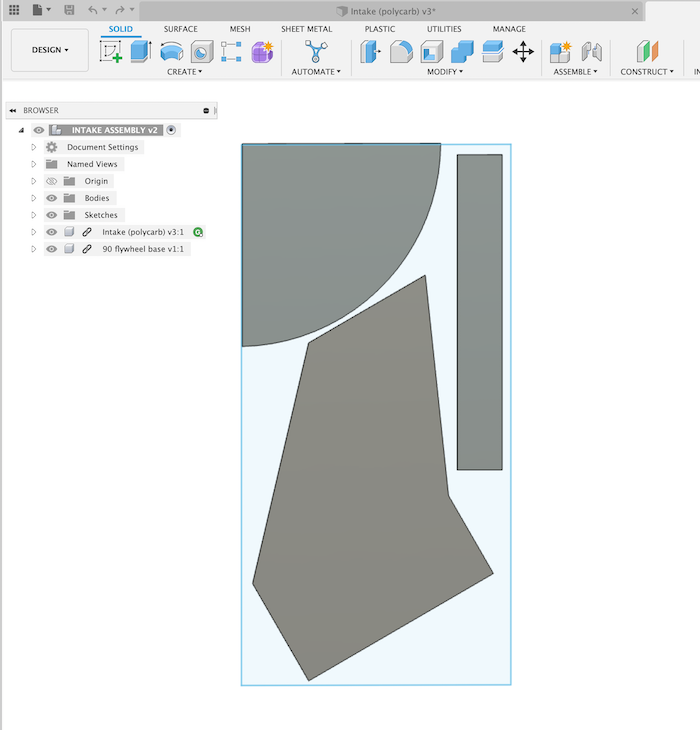

Sketch a rectangle that is 12 by 24 inches. Use insert into current design to add all your parts to this assembly. Use move tool to lay them out on the rectangle to fit. If you cannot fit in the required size you may have to redesign some parts.

Cutting

Poly carb sheets can be cut with scissors. They need to be the type of scissors used for cutting metal, sometimes called tin snips. We affectionately call them the Ukrainian Scissors.

Straight cuts can be made on the band saw. Sometimes the sheet is too big to cut on the band saw. Also do not try to make curved cuts on the band saw as it is not designed to do that and the blade could come loose.

Drilling Holes

Punching Holes

Cutting on the X-Carve

The x carve is a 2D cnc machine. It is a cutter that can be moved by computer control over a large 2 dimensional plane.

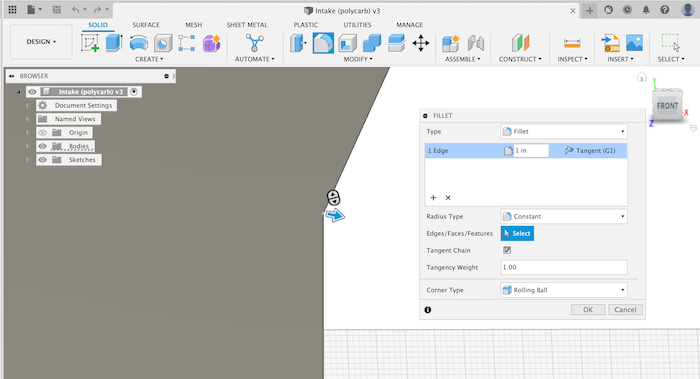

Internal fillets should have a radius larger than the tool radius. Can also be made to give a more gradual bend to the cut feature.

Multiple edges can be selected with Shift+click then a value for the fillet radius. This will make all of the edges have the same fillet.